Oil & Grease Removal From Water

H2K Technologies offers industrial treatment equipment to remove free-phase and emulsified oils from water.

It’s common knowledge that oil and water don’t mix, so why is oil removal from water a challenge for many water treatment facilities? Oil and water will separate from each other when provided enough time and volume to do so, but most wastewater processes do not have the luxury of infinite settling time or plant space. Engineered oil/water separators take many shapes and selecting the right unit for your facility is critical to keeping your water treatment system operational. Oil type, product weight, specific gravity, viscosity, and droplet size all factor in what solution is the best fit to remove oil from water. H2K Technologies provides oily water solutions capable of handling free-phase and emulsified oils.

Industrial Oil/Water Separators

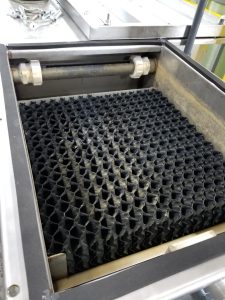

Coalescing oil/water separators are the best performance option when removing free phase oil & grease from water. This style of oil/water separator utilizes an engineered oil coalescing media to capture oil droplets and accelerate the oil separation process. The honeycomb media design increases surface area and creates laminar flow, both greatly increase the rate that oils are separated from water. Separated products accumulate at the water surface and are skimmed off into a product drum or tank. Sizing a coalescing oil-water separator depends on oil weight and type. These separators are capable of removing any free-phase products; lighter oils will be more quickly separated than heavier oils.

Cartridge Filters & Bag Filters for Oil

Free-phase oil is easily managed with our oily water separator but emulsified products often require a specialty filter solution. Emulsified oil & grease describes smaller oil particles that are well-mixed in water that require much longer time to separate. Oil emulsification can be created by tank mixers, centrifugal pumps, and chemical additions to water.

These emulsified oils are difficult to remove from water, but we supply custom bag filters and cartridge filters capable of capturing emulsions. These custom filters utilize an engineered oleophilic coating in the cartridge which captures any hydrocarbons present in the water. Oil removal cartridges and bag filters capture both emulsified and free-phase oils with a single pass through the housing. Filters are manufactured for use with standard size housings, so system retrofits are feasible with minimal re-installation onsite.

Organoclay Media

Organoclay is a specialty media designed to capture emulsified oils from water. This granular filter media is harvested from naturally occurring zeolite and is designed for installation in media vessels. Oil capture capacity is up to 70% of it’s own weight which provides a long lifespan before media changeout is required. Organoclay also is capable of removing select cations & anions including magnesium, ammonia, calcium, and more. This granular organoclay media allows pressurized flow through the filter to eliminate the need to add a transfer pump to repressurize water. Available mesh sizes include 8×14 and 14×40.

Integrated Water Treatment Systems

Oil and grease treatment is a critical component when free product is present in a water treatment system. Performance of sand filters, carbon filters, air strippers, and other process equipment is greatly affected when impacted by oil and grease. Oils introduced to media filters will become stuck in that media and clog the system, this will reduce performance and reduce lifespan of the filters. H2K Tech’s skilled engineering team has the experience to design a packaged treatment system capable of handling complex water processes. Our knowledge of water impacted by oils & grease, dissolved metals, suspended solids, VOCs, and more allows us to provide turnkey water treatment for a broad range of processes. Call us today and we’ll work with you to provide the best oil & grease solution for your water treatment facility.